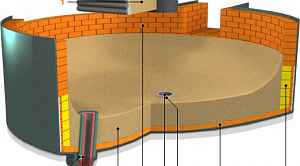

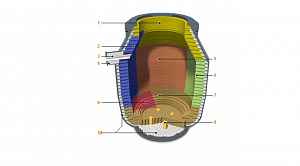

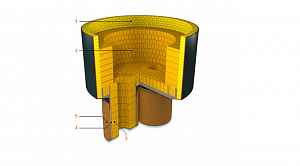

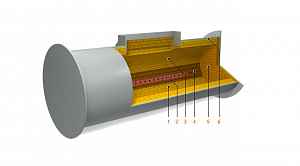

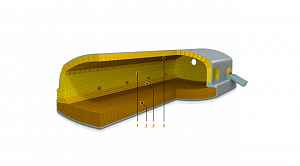

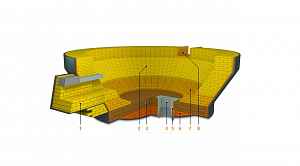

Lining zones:

- Cooling zone

- Lower transitional zone

- Sintering zone

- Upper transitional zone

- Preparation zone

Download 3D model of the unit, (.mov)

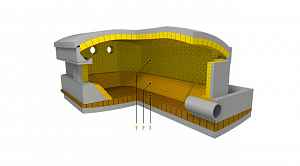

Magnezit Group offers the whole complex of refractories for cement clinker burning and lime calcining units.

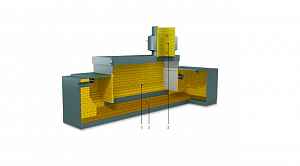

The activity basis of the Group is the manufacture and realization of high — quality refractory products, and also rendering of services for completing and operation clients’ thermal units.

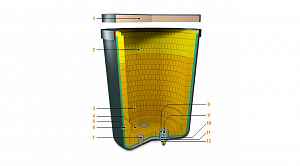

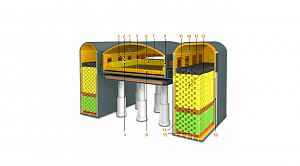

Magnezit Group fulfils the design of units lining using fire-resistant materials, the combination of which depends on the furnace diameter and its operating features. We can offer the variants using metal plates and pasteboard compensators (plates) glued onto the appropriate sides.

Completeness of supply provides Consumer with all fire-resistant materials using at rotary kilns lining. For the purpose of carrying out of high — quality assembling and provision of assured resistance of lining, the complete list of auxiliary equipment (such as cutting machines and mixers) is offered. We also offer the complex of services for lining accomplishment and assistance in monitoring for the period of unit operation.